Table of Contents

Awesome Benefits of 3D Printing in Prototyping

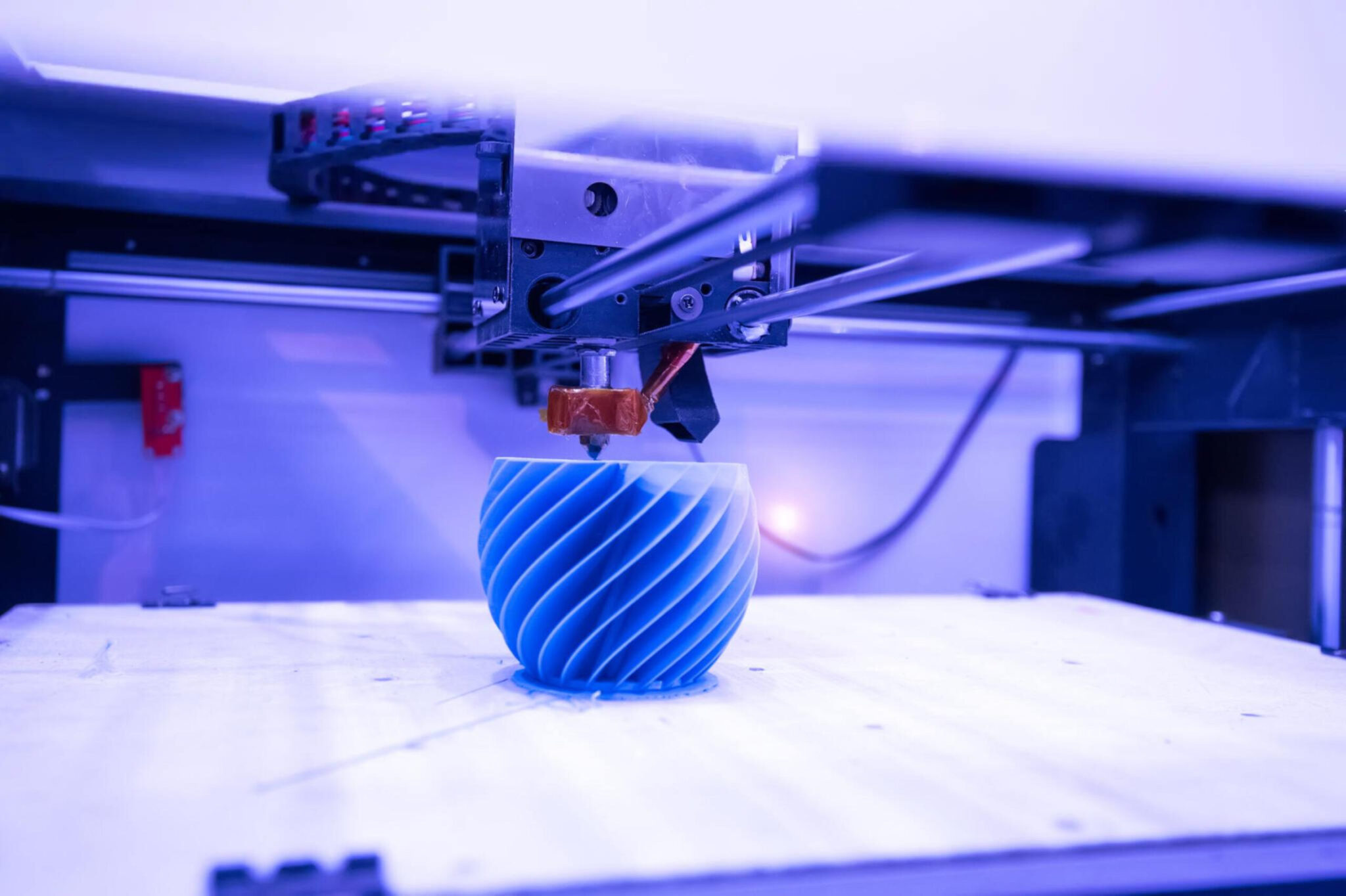

What Is 3D Printing?

First things first, what exactly is 3D printing? Imagine you have a regular printer that prints on paper, but instead, it prints layer by layer to create a 3D object. That’s 3D printing! It’s like building something out of Lego bricks but way more advanced.

Why Prototyping?

Before any product hits the shelves, it starts as a prototype. A prototype is basically a first draft of an invention, like a rough version of a new toy or gadget. It helps inventors test their ideas and see what works and what doesn’t.

The Magic of 3D Printing in Prototyping

So, how does 3D printing revolutionize prototyping? Let’s check out some key benefits:

Speedy Gonzales!

With traditional methods, making a prototype can take weeks or even months. But with 3D printing, you can whip up a prototype in just a few hours! This means you can test and tweak your designs way faster.

Cost Savings

Imagine having to pay for expensive molds or tools every time you want to make a prototype. That can get pricey! 3D printing skips all that, so you save a ton of money. Plus, you only use the material you need, which is super efficient.

Complex Designs? No Problem!

3D printing lets you create intricate and detailed designs that are impossible with traditional methods. Whether it’s a tiny part of a machine or a detailed figurine, 3D printers can handle it all.

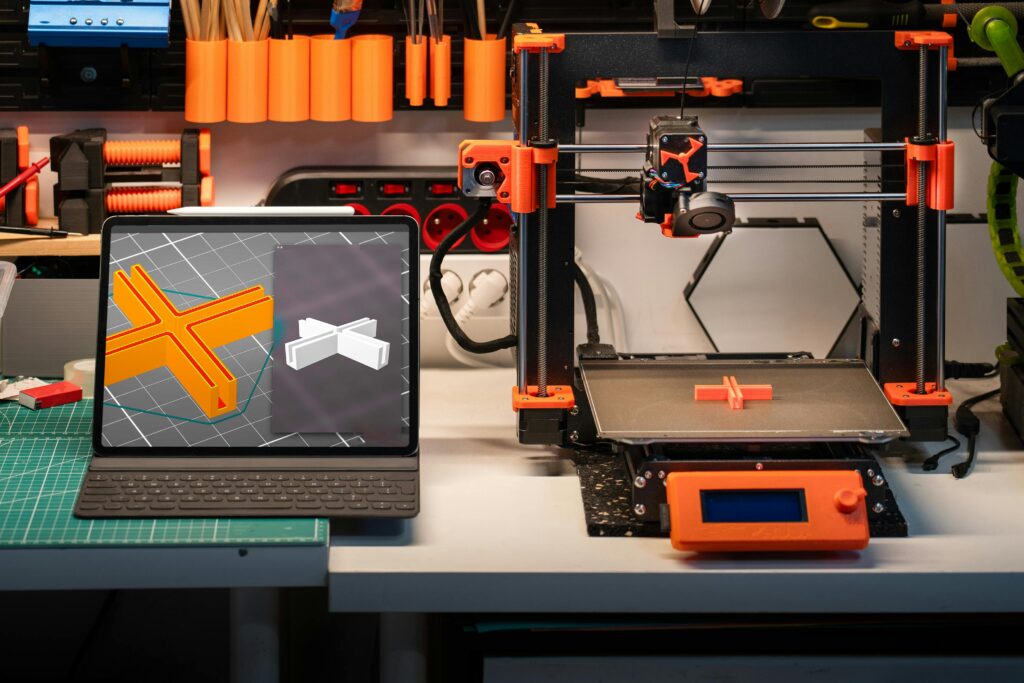

Easy Peasy Customization

Need to make a change to your design? No sweat! With 3D printing, you can easily tweak your digital model and print a new version in no time. This flexibility is perfect for inventors who love experimenting.

Reduce Waste

Traditional manufacturing often creates a lot of waste. But 3D printing is super eco-friendly. Since it builds objects layer by layer, there’s very little waste. Yay for the environment!

Real-World Applications of 3D Printing in Prototyping

To truly appreciate the impact of 3D printing on prototyping, let’s look at some real-world examples:

- Aerospace: Companies like Boeing and Airbus use 3D printing to create complex parts for aircraft. These parts are lighter and stronger, contributing to better fuel efficiency and performance.

- Healthcare: 3D printing is used to create custom prosthetics and implants tailored to individual patients, improving comfort and functionality.

- Automotive: Car manufacturers use 3D printing to produce prototypes of new components quickly, allowing for rapid testing and iteration.

Wrapping Up

3D printing is totally transforming the way we create prototypes. It’s fast, cost-effective, and incredibly versatile. For anyone dreaming up the next big invention, 3D printing is a game-changer.

So, the next time you see a cool new gadget, remember that it probably started as a 3D printed prototype. How awesome is that?