Table of Contents

Different Types of 3D Printing Technologies

Exploring Different Types of 3D Printing Technologies

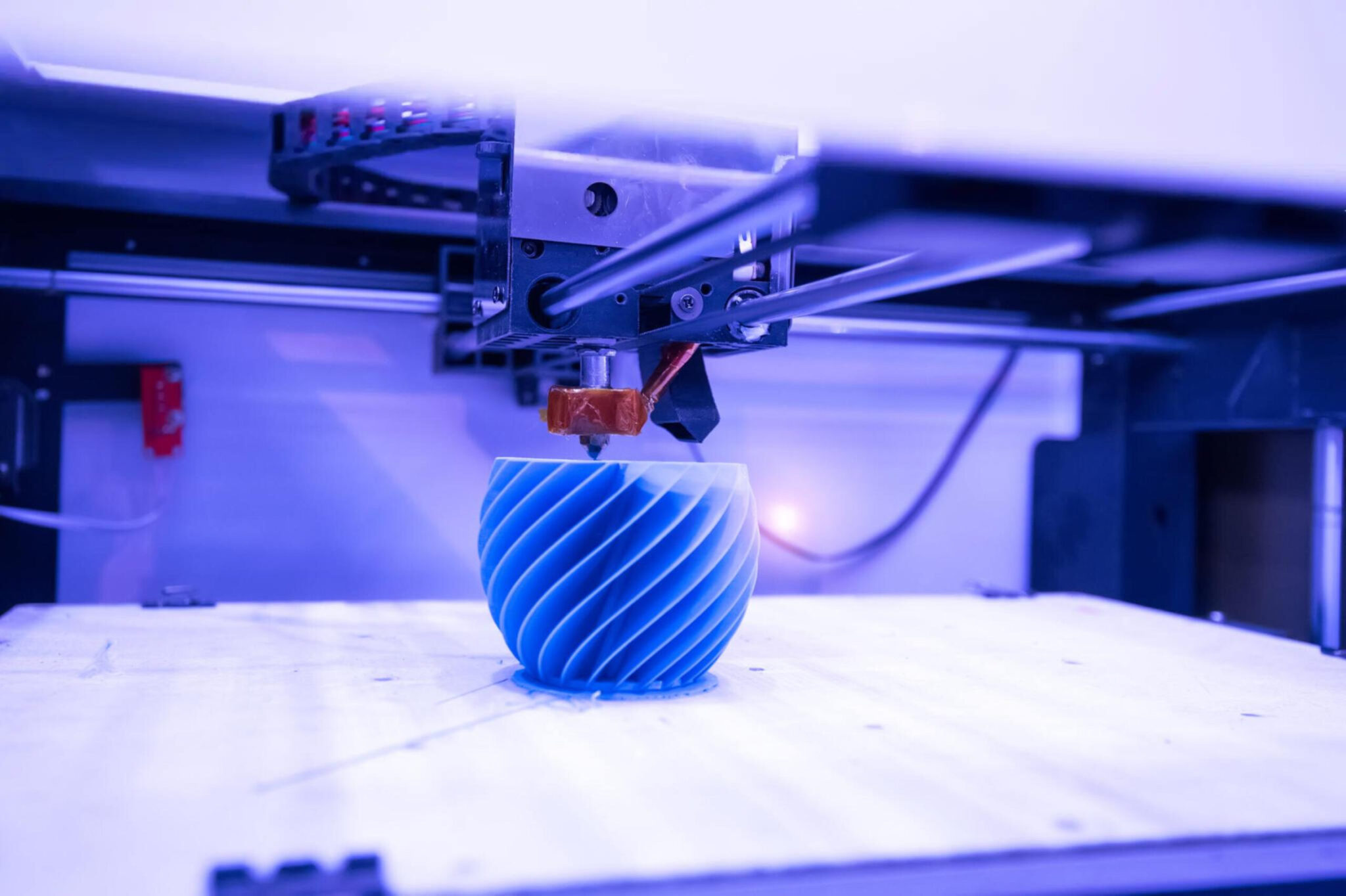

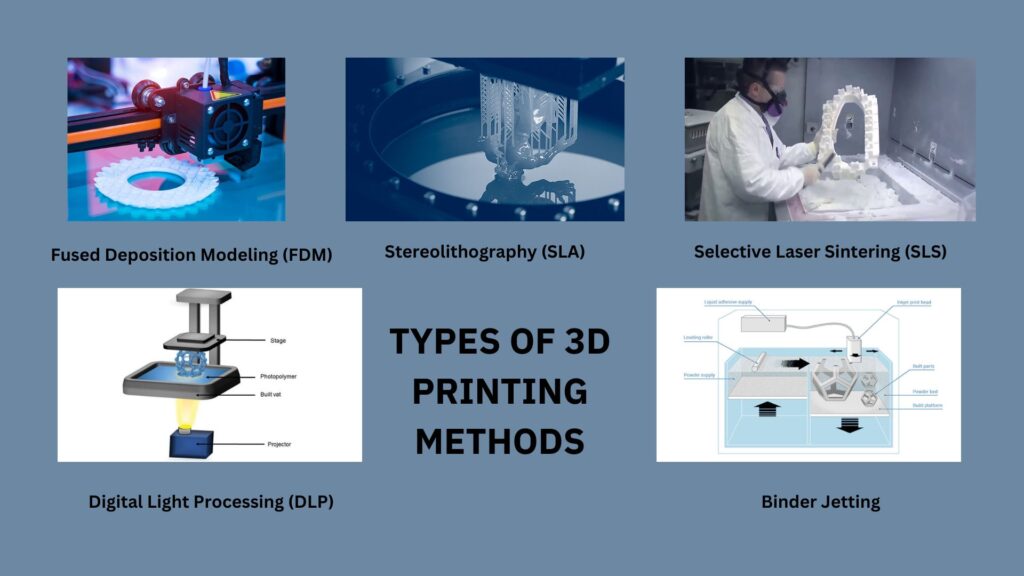

3D printing is a fascinating technology that has revolutionized the way we create and manufacture objects. There are several different types of 3D printing technologies, each with its own unique methods and applications. In this blog, we’ll explore five popular types of 3D printing: Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS), Digital Light Processing (DLP), and Binder Jetting.

1. Fused Deposition Modeling (FDM)

How It Works: FDM is one of the most common types of 3D printing. It works by extruding a thin filament of thermoplastic material through a heated nozzle. The nozzle moves layer by layer, depositing the material onto a build platform where it cools and solidifies to form the desired shape.

Applications:

- Prototyping

- Functional parts

- Educational projects

Advantages:

- Cost-effective

- Easy to use

- Wide range of materials

Limitations:

- Lower resolution compared to other methods

- Visible layer lines

2. Stereolithography (SLA)

How It Works: SLA uses a UV laser to cure (harden) a liquid resin into solid plastic. The process begins with a platform submerged in a vat of liquid resin. The UV laser traces a pattern on the resin surface, curing it into a solid layer. The platform then lowers slightly, and the next layer is traced on top of the previous one. This continues until the object is fully formed.

Applications:

- Highly detailed models

- Jewelry

- Dental and medical models

Advantages:

- High resolution and detail

- Smooth surface finish

Limitations:

- More expensive than FDM

- Limited material options

3. Selective Laser Sintering (SLS)

How It Works: SLS uses a high-powered laser to fuse small particles of powdered material into a solid structure. The laser selectively sinters the powder by scanning cross-sections generated from a 3D digital model. After each layer is sintered, a new layer of powder is spread over the build area, and the process repeats.

Applications:

- Functional prototypes

- End-use parts

- Complex geometries

Advantages:

- No need for support structures

- Durable and functional parts

- Wide range of materials

Limitations:

- High cost

- Powder handling can be messy

4. Digital Light Processing (DLP)

How It Works: DLP is similar to SLA but uses a digital light projector to cure the resin instead of a laser. A digital micromirror device (DMD) projects the image of each layer onto the surface of the resin, curing it all at once. The platform then moves down, and the next layer is projected and cured.

Applications:

- Highly detailed models

- Jewelry

- Dental and medical models

Advantages:

- Fast printing speeds

- High resolution

- Smooth surface finish

Limitations:

- More expensive than FDM

- Limited material options

5. Binder Jetting

How It Works: Binder jetting involves spreading a thin layer of powdered material, such as metal, sand, or ceramic, onto a build platform. A print head moves across the layer, depositing a liquid binding agent that binds the powder particles together. The platform then lowers, and the process repeats layer by layer until the object is complete. The final object may require additional processing, such as sintering, to enhance its properties.

Applications:

- Sand casting molds and cores

- Metal parts

- Full-color prototypes

Advantages:

- Can print in a wide range of materials

- Fast production speeds

- Capable of full-color printing

Limitations:

- Requires post-processing

- Mechanical properties can vary

Conclusion

3D printing technologies offer a variety of methods to create objects, each with its unique advantages and limitations. Whether you need highly detailed models, functional prototypes, or custom parts, there’s a 3D printing method that suits your needs. Understanding the differences between these technologies can help you choose the right one for your project.