Table of Contents

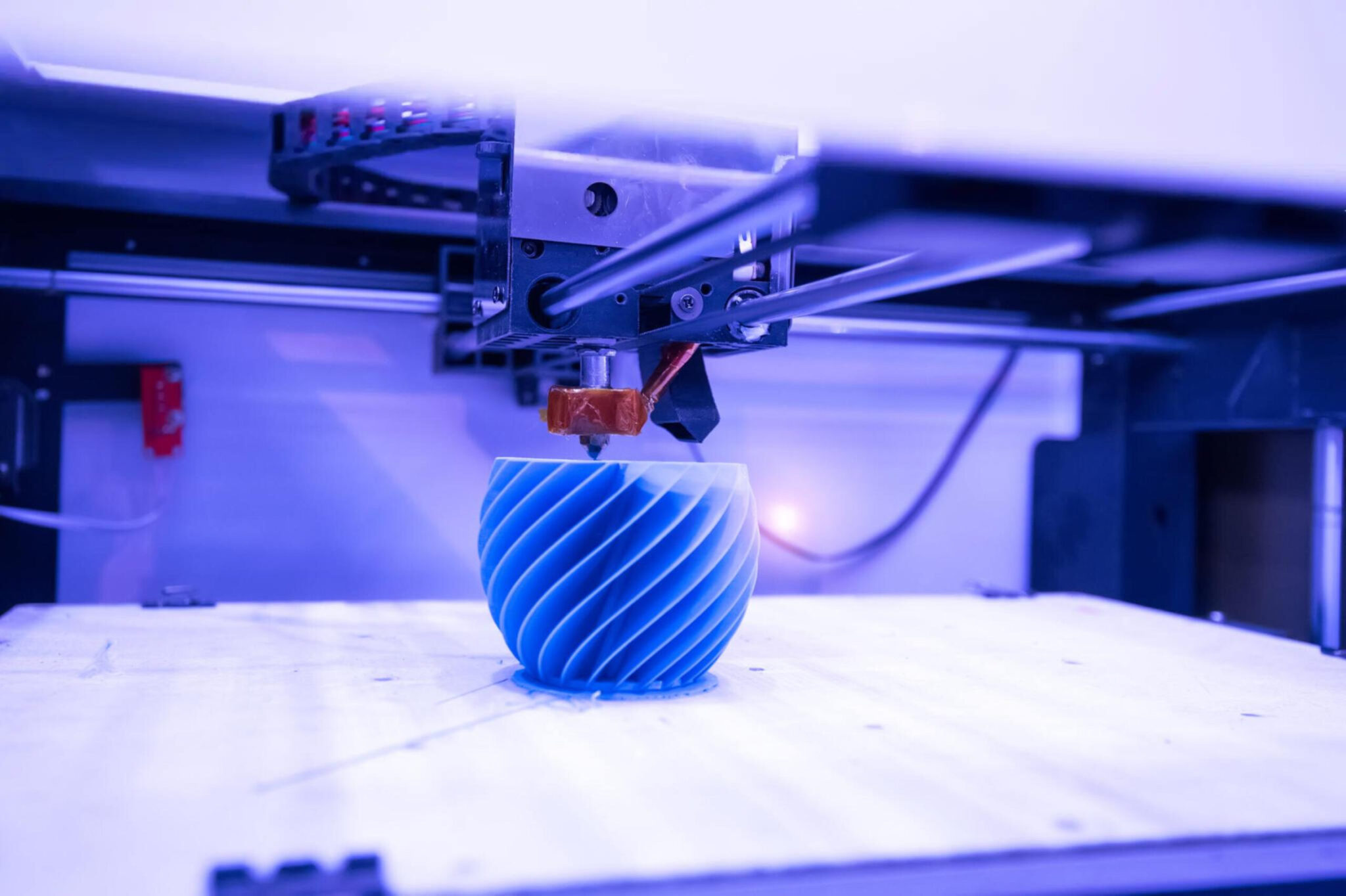

Stereolithography (SLA)

Exploring SLA Additive Manufacturing: A Deep Dive

Stereolithography (SLA) is a groundbreaking additive manufacturing technology that has significantly impacted the way we create detailed and high-quality prototypes and parts. This blog will provide an in-depth explanation of SLA, detailing its process, advantages, disadvantages, and applications. By the end, you’ll have a thorough understanding of why SLA is a preferred method for many industries.

What is SLA?

Stereolithography (SLA) is a type of additive manufacturing technology that uses a UV laser to cure liquid resin into hardened plastic. Developed in the 1980s, SLA was the first 3D printing technology and remains one of the most precise and versatile methods available.

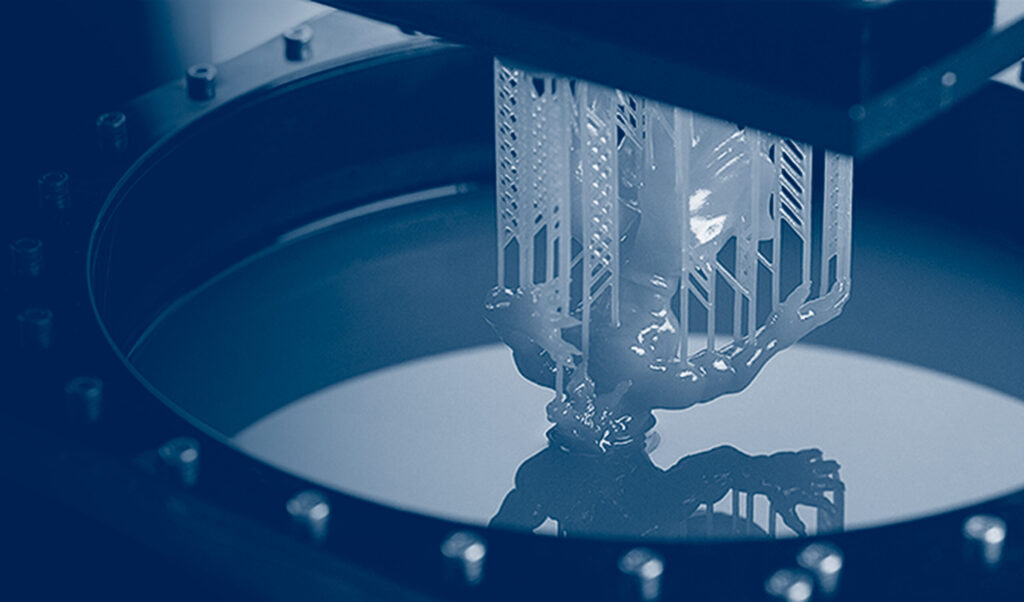

How Does SLA Work?

The SLA process involves several critical steps:

Design: The journey begins with a digital 3D model created using Computer-Aided Design (CAD) software. The model is then converted into a format that the printer can interpret, typically an STL (stereolithography) file.

Preparation: The digital model is sliced into thin horizontal layers using slicing software. This software generates a G-code file, which provides the printer with detailed instructions on how to build each layer.

Printing: The SLA printer contains a vat of liquid photopolymer resin. A build platform is submerged into the resin, just below the surface. A UV laser traces the first layer of the design on the resin surface, curing and solidifying the material. The platform then lowers slightly, and the next layer is traced and cured. This process is repeated until the entire object is built.

Post-Processing: Once printing is complete, the object is removed from the vat and rinsed in a solvent to remove excess resin. It may also undergo additional curing in a UV oven to ensure full hardness and stability. Further post-processing steps can include sanding, priming, and painting to achieve the desired finish.

Advantages of SLA

SLA offers numerous benefits that make it a popular choice for detailed and high-quality manufacturing:

High Resolution and Precision: SLA is known for its exceptional detail and accuracy. It can produce complex geometries with fine features and smooth surfaces, making it ideal for high-resolution applications.

Smooth Surface Finish: The cured resin produces a smooth surface finish that requires minimal post-processing. This is particularly beneficial for prototypes and end-use parts that need a high-quality appearance.

Material Versatility: SLA resins come in a wide variety of formulations, including rigid, flexible, castable, and biocompatible materials. This versatility allows for diverse applications across different industries.

Strength and Durability: SLA parts are generally strong and durable, capable of withstanding mechanical stress and environmental factors, depending on the resin used.

Rapid Prototyping: SLA is suitable for rapid prototyping, enabling quick iteration of designs. This accelerates the product development cycle and helps bring products to market faster.

Disadvantages of SLA

Despite its many advantages, SLA also has some limitations:

Material Costs: SLA resins are typically more expensive than the filaments used in other 3D printing technologies like FDM. This can increase the overall cost of production.

Post-Processing Requirements: SLA parts require post-processing to remove excess resin and achieve full hardness. This can be time-consuming and may require additional equipment.

Limited Build Size: SLA printers often have smaller build volumes compared to other 3D printing methods, limiting the size of objects that can be produced in a single print.

Sensitivity to Light and Heat: SLA resins can be sensitive to prolonged exposure to light and heat, which may affect the durability and longevity of printed parts.

Environmental and Safety Concerns: Handling liquid resin requires safety precautions, including protective gear and proper ventilation, as the materials can be hazardous.

Applications of SLA

SLA’s precision and versatility make it suitable for a wide range of applications across various industries:

Prototyping: SLA is ideal for creating detailed and accurate prototypes, allowing designers to test and refine their ideas before mass production.

Dental and Medical Models: SLA is widely used in the dental and medical fields to produce custom models, surgical guides, and biocompatible implants.

Jewelry: Jewelers use SLA to create intricate wax models for casting, allowing for the production of highly detailed and customized pieces.

Engineering and Manufacturing: SLA is used to produce functional parts, jigs, and fixtures for engineering and manufacturing applications, where precision and durability are crucial.

Consumer Products: From eyewear to custom-fit gadgets, SLA is used to produce a variety of consumer products that require high detail and a smooth finish.

Conclusion

Stereolithography (SLA) is a powerful and versatile additive manufacturing technology that excels in producing high-resolution, detailed, and smooth-finished parts. Its precision and material versatility make it a go-to choice for industries ranging from healthcare to jewelry. While it has some limitations, the benefits of SLA often outweigh the drawbacks, making it a valuable tool in modern manufacturing.

By understanding the intricacies of SLA, you can better appreciate its role in the world of 3D printing and how it can benefit your projects. Whether you’re a designer, engineer, or hobbyist, SLA offers a reliable and efficient solution for bringing your ideas to life.